In today’s precise industrial world, quality control isn’t helpful—it’s essential. Manufacturers in all industries face growing pressure. They must deliver parts and products that meet precise specifications. There’s no room for error. Vision measurement systems are key tools. They ensure product accuracy, boost efficiency, and enhance long-term reliability.

The Shift Toward Non-Contact Precision:

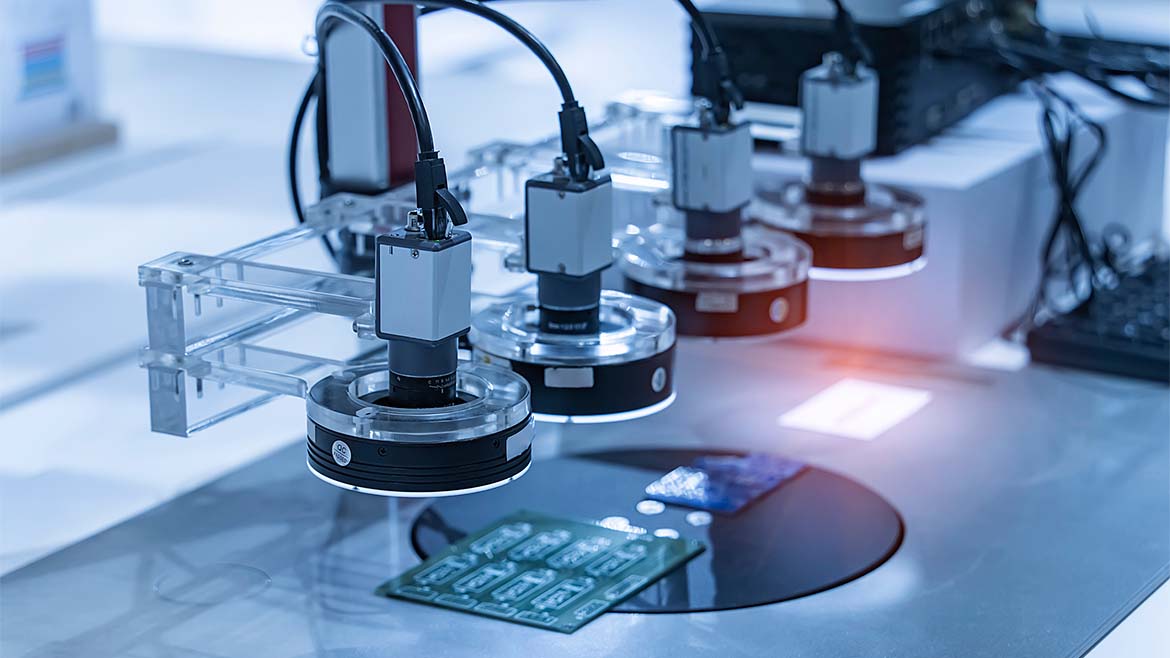

Traditional tools, such as calipers, gauges, and CMMs, have long been used in the industry. As production gets more complex and tolerances tighten, contact-based systems show their limits. Vision measurement systems (VMMs) provide a new way to inspect without contact. They deliver micron-level precision, quick processing, and smart automation features.

These systems rely on high-resolution cameras, sensors, and smart image-processing algorithms. They measure and analyze component dimensions, geometry, and position. They do all this without touching the part. This reduces deformation risks and significantly enhances speed and repeatability.

Key Benefits of Vision Measurement Systems:

1. Micron-level accuracy:

One of the most crucial aspects of quality control is precision. Modern VMMs can achieve accuracy as fine as ±0.1 microns, depending on the model. This level of detail ensures that even complex features provide reliable measurements. This is crucial in fields like aerospace, medical devices, and electronics.

2. Non-Contact Measurement:

Soft or bendable parts can change shape with touch, causing incorrect measurements. Vision measurement systems solve this problem completely. They use optical methods to keep the inspected components intact.

3. Increased throughput:

These systems can inspect many components with speed and reliability. They offer automation options and programmable measurement sequences. This cuts down on bottlenecks in production lines. It also keeps quality checks steady, unlike human inspection, which can vary.

4. Advanced Data Analysis:

The integration of intelligent software allows for immediate data analysis and trend tracking. Engineers and quality control staff can make reports. They can use statistical process control (SPC) to link each measurement to its source. This supports continuous improvement and informed decision-making.

Application Across Key Industries:

Vision measurement systems are versatile and adaptable across multiple sectors:

- Automotive: Ensuring dimensional accuracy in engine components and safety-critical parts.

- Electronics: Measuring micro-sized circuit boards and components where traditional tools fall short.

- Aerospace:

- Keeping high precision for parts that work under stress or in tough conditions.

- Medical Devices: Ensuring that small, complex tools meet strict rules for accuracy.

What Sets Meaxpert Apart?

Pick a trusted and skilled provider when investing in a vision measuring system. Meaxpert is a top maker and supplier of high-performance VMMs. These VMMs feature advanced hardware, a strong design, and smart software.

Meaxpert offers a wide range of systems, including:

- URANUS Series: This is a fully automated VMM. It offers high-speed and high-precision features. It’s perfect for high-volume production.

- SATURN Series: CNC gantry-style machines for measuring large components with stability and precision.

- PLUTO Series: Manual systems for low to medium volume inspections with quick setup.

- NEPTUNE Series: Semi-automated systems offer a balance of flexibility and automation.

Each system includes:

- Programmable LED lights

- High-definition CCD cameras

- High-resolution linear scales

- Multi-axis motion control

- Meaxpert’s machines work for both 2D and 3D measurements. They offer the versatility to meet various measurement needs.

Built for durability and long-term accuracy

What makes Meaxpert’s systems particularly unique is their design philosophy. These machines feature:

- Hard-anodized workbenches that withstand long-term industrial use.

- Anti-drop Z-axis screws for added safety and precision.

- Stable steel column structures that reduce vibration and ensure consistent results.

- Advanced motion control motors offer fast, silent positioning.

This attention to detail ensures accuracy and low maintenance. It also offers long-term stability. This helps reduce the total cost of ownership for the user.

Smart Software for Smarter QC

Meaxpert’s vision systems include strong software, such as External-Array RationalVue. This software provides advanced 2D and 3D composite measurement features. Users enjoy automated inspections, CAD model comparison, and customizable reporting features. This helps teams simplify their QC workflows. It reduces errors and keeps them compliant with international standards.

Choosing the Right Vision Measurement System

When selecting a VMM, it’s crucial to assess:

- The complexity and size of the parts.

- Required tolerances and measurement accuracy.

- Production volume and the need for automation.

- Budget constraints and room for future expansion.

https://meaxpert.com/ makes this easier. We provide expert consultations, demo support, and personalized advice. This helps clients pick the best system for their needs.

Final Thoughts

Adding vision measurement systems to your quality control strategy is essential. It transforms everything. They offer unmatched accuracy, speed, and data integrity. This is crucial in today’s tough manufacturing market.

Meaxpert has a strong history of success. We provide advanced solutions. These include measurement machines and complete quality assurance systems tailored for you. Improve your quality control now. This applies to aerospace, automotive, electronics, and manufacturing.

Discover Meaxpert’s range of vision measurement systems. See how innovation can boost your measurements.